A leading manufacturer in Germany wanted to visualize and analyze their manufacturing quality across all plants for quality monitoring and to discover improvement opportunities in a data-driven way.

About the Client

Problem Statement

- Time for feature deployments

- Static reporting

- Performance (long response time)

- Analysis over multiple plants was not possible

The Challenge

- New KPI definitions couldn’t be analyzed because the current reporting solution didn’t provide them and feature requests took a long time

- Ad-hoc analysis was inefficient due to the long response time

- No access to the raw data made self-service analysis impossible

- Customized reports could not be created as the data was not available in a user-friendly way

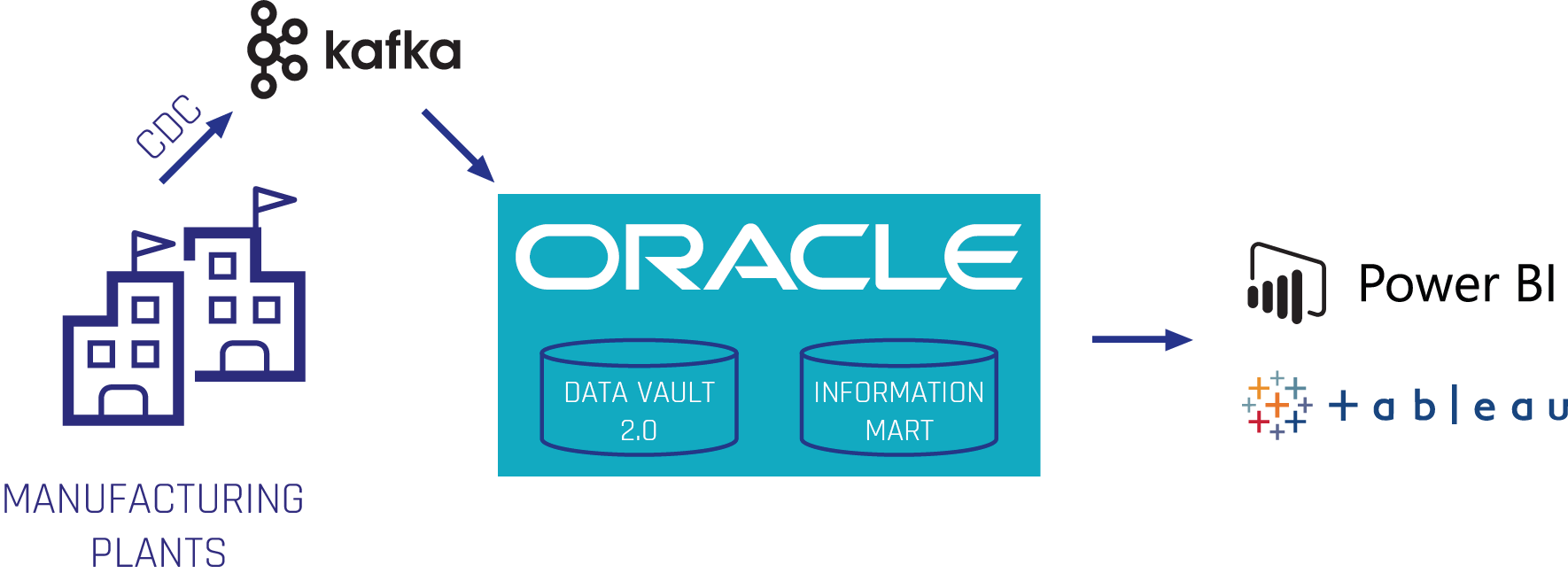

The Solution

- Raw data from multiple source systems is accessible

- Data is integrated by business understanding

- Good performance due to pre-aggregation of KPIs

- Maintenance can be performed by an internal team

- Faster feature deployments

Tangible Results for the Client

Interested in learning more? Get the detailed case study!

Trung Ta

Senior Consultant

Phone: +49 511 87989342

Mobile: +49 170 7431870

Free Initial Consultation